Inventory Control with UHF

December 30, 2023

The operator of plants previously used here a combination of standardized manual steps and semiautomated computer management in the warehouse. This neither produced the required logistics efficiency nor minimized error quotas. An excessively large number of work steps were required just to place or find material or organize the stock levels for slightly varying types of goods. In view of the increased demand for the quality of logistics services, it was particularly necessary to ensure correct purchasing and inventory controls.

In the warehouse

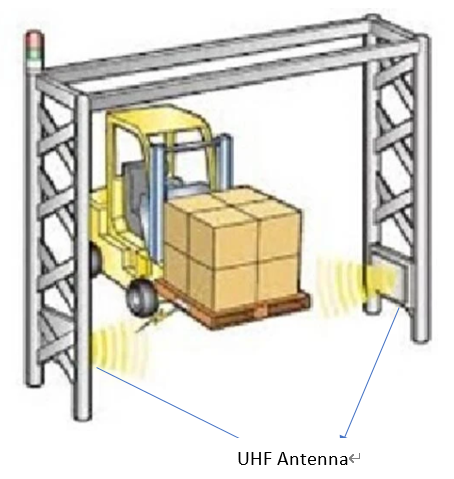

SR-RU12MG03B01readers are installed in the warehouse along the automated conveying line. They record incoming and outgoing goods movements and also register the exact position of the pallets.

More real-time ERP information with UHF RFIDWhen did material reach or leave the warehouse and how much? What items were involved? Where are the products stored? The ERP system has to make this information visible in real time and provide it on demand on the transported material. Syncotek therefore opted for data transmission via UHF-RFID. In brief: read/write heads use a high frequency signal to write or read a specific amount of information to or from passive RFID tags and to transfer it to the IT network via an interface. Thanks to the UHF technology the exchange is carried out between the reader and the tag over several meters. Information is also captured when objects pass at high speed.

Read/write head connects material data with the pallet

The company transports goods on returnable pallets. An RFID tag which is provided with a unique ID is embedded in each transport pallet in order to link the data closely to the material or product conveyed. This tag is written for the first time in the packaging area. It is here that SR-RU120G08A read/write head virtually “marries” the specific material information with the pallet before it reaches the goods center. The transmission of the cube-shaped UHF reader complies with ISO 18000-6C, and thanks to its IP67 protection type can operate if necessary in harsh environments with temperatures between -20 and +50 °C.